Wolters Europe and sustainability

Fair and sustainable use of EPS & EPP

Environmentally aware and socially involved. Wolters Europe is investing in reducing its ecological footprint. We invest in the realization of innovative products, where quality and sustainable aspects come together. In this way we can provide you with high-quality products and we reduce our impact on the environment.

ISO 14001

Wolters Automotive has this environmental certification and works in accordance with the directive. ISO 14001 describes the core elements for setting-up, implementing, maintaining and improving an environmental management system: formulating environmental policy, establishing environmental aspects and effects, drawing up environmental objectives and programs and implementing an environmental management system focused on the continuous improvement of environmental performance.

Solar panels

Our roof on the Vonderweg is covered with almost 1,900 solar panels. The CO2 reduction that we achieve with this is equal to the growth of 13,000 trees per year!

Energy consumption

Like every modern company, we take energy-saving measures on a daily basis. Think of LED lighting and reusing heat from our production process. Our fleet of vehicles is also becoming greener. We reduce our transport movements through the use of LHV trucks.

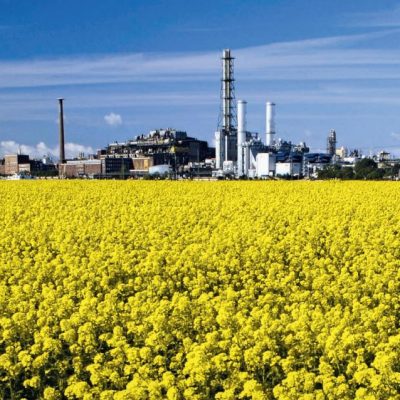

Sustainable alternative to gas: Wolters Europe uses steam for its production process, steam is produced with natural gas. We are currently working with partners (more will be announced soon) to make our steam generation more sustainable. Our goal is to minimize gas consumption and to use the residual heat released by the process of our companies in the Netherlands for the development of a heat network.

The aim of these sustainable measures is to prepare our company for a sustainable future!

100% recyclable

EPS and other expanded materials consist of one type of material, which makes it ideal for recycling. Wolters Europe uses EPS and EPP in the manufacture of its products. Production outages in our companies are processed in our recycling department as much as possible and be added to new products to be manufactured. This applies to the locations in the Netherlands and the Czech Republic. Projects with pilot customers are currently underway to investigate whether used products can be taken back from our customers and to add this to new products to be manufactured.

Packaging materials are almost completely reused within our company and the supply chain. This concerns specific reusable customer packaging up to and including cardboard packaging materials.

Innovation regarding EPS and EPP

Wolters Europe already offers the market products made of 100% compostable bio plastics. With this application, our customers have a 100% recyclable alternative to traditional EPS.

Together with raw material suppliers and customers, Wolters Europe has entered into partnerships to stimulate and accelerate the re-use of EPS and EPP. There are many initiatives, we believe that through collaboration in the supply-chain, innovations grow the fastest.

Initiatives with regard to the re-use of plastic and EPS are also taking place in the Twente region. Wolters takes its responsibility in this and supports these initiatives, including purEPS.

25% recycled content in EPP

Together with supplier JSP, we are investigating at various car manufacturers the possibility of adding 25% recycled EPP to the various parts we produce. In this way we contribute to a saving of 12% CO2 emissions compared to only new material.

Biomass Balance Approach

In the Biomass Balance Approach, renewable sources such as bio-naphtha or biogas derived from organic waste or vegetable oils are used together with fossil sources in the very first steps of chemical production. The biobased amount is then mathematically allocated to specific products that are provided via the certified method.

Airpop, 98% air

Wolters Europe takes its responsibility with regard to sustainability. However, we believe that there is a lot of misunderstanding about plastics and that plastic is often criticized on social media..

It is important to emphasize that current products made of EPS and EPP consist of 98% air, so the required raw materials are already being used very efficiently. In addition, our current EPS and EPP products can already be recycled very well: AIRpop promo recycling

We would also like to draw your attention to the plastic truth vs. campaign. plastic fable, a nuance in the debate about plastic through 8 facts & fables. The plastic truth